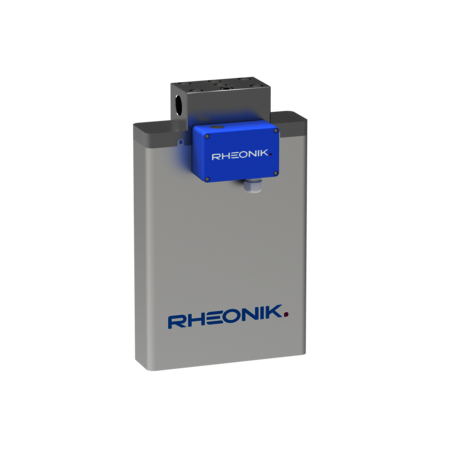

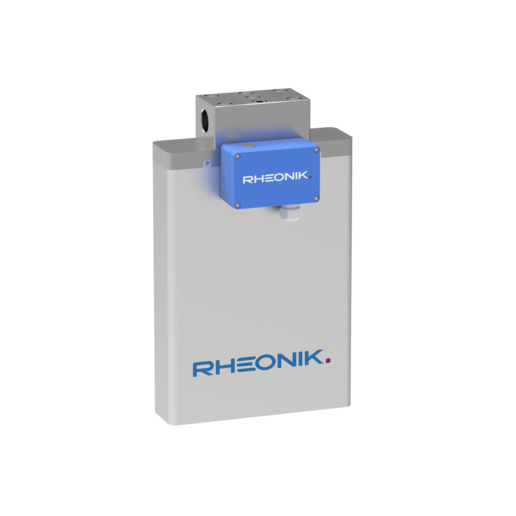

RHM 20

FLOW SENSOR

The RHM 20 is a 2″ meter designed for general purpose flow measurement without the need for maintenance. Robust and accurate, the RHM 20 outperforms other flow technologies at an attractively low cost of ownership.

- Range: 1 kg/min up to 480 kg/min

- Pressure: up to 400 bar (5801 psi)

- Temperature: -50°C (-58°F) up to +210°C (410°F)

- Accuracy: 0.1 % of rate

- Materials: SS 316L / SS 316Ti, Alloy C22 – 2.4602, Tantalum – UNS R05200, Super Duplex – 1.4410

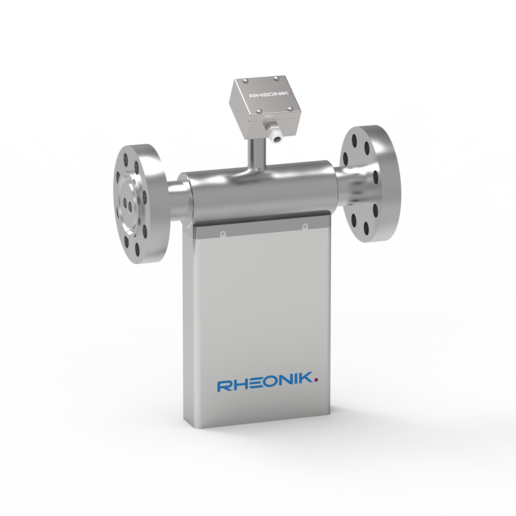

- Process Connection: 1" up to "

General Specifications

Nominal Flow (Qₙₒₘ)* | 300 kg/min (661.4 lb/min) |

Maximum Flow (Qₘₐₓ)* | 480 kg/min (1058.22 lb/min) |

Typical Minimum Flow (Qₘᵢₙ)* | 1 kg/min (2.2 lb/min) |

Serial Tube / Single Path | Flow rates Qmax, Qnom and Qmin for "serial" sensors will be 50% of the above listed parallel/dual path version. |

Operating Temperature | Fluid temperature range options cover applications from -196°C to 350°C (-320°F to 662°F). |

Ambient Temperature | -50 °C to +80 °C (-60 °F to +180 °F) (standard), versions available for installation in vacuum chamber (-260 °C / -430 °F) or oven (up to +210 °C / +410 °F) (optional) |

Pressure Ratings | Up to 1379 bar / 20000 psi - dependent upon material |

Electrical Connection Sensor | M20 x 1.5 standard cable entry for JM, SM terminal box versions Optional entries available: ½” NPT or M25 x 1.5 (only for SM) or ¾″ NPT (only for SM) M16 x 1.5 standard cable entry for PM terminal box version Max. cable length to remote RHE transmitter 100 m/330 ft |

Sensor Enclosure Materials | Stainless steel 304 (standard), SS 316 (optional) Coated aluminum terminal box, SS 316 terminal box (optional) |

Enclosure Type | Protection class IP66, NEMA 4X (standard), IP66/67, NEMA 4X/6 (optional) |

Wetted Materials | Flow tubes SS 316Ti, Alloy C22, Tantalum or SuperDuplex Manifolds SS 316L; Seal material (manifold construction): PTFE Standard flanges SS 316Ti, other connections SS 316L Additional/customer specific materials available upon request |

Process Connections | Nearly any – the Rheonik AnyPipeFit Commitment. Consult factory for types/sizes not listed in this data sheet on the Mechanical Construction pages |

Pressure Rating Compliance | Europe – PED: Sound Engineering Practice (SEP), Module A2, Module B3.1+C2 Canada – CRN: Canadian Registration Number |

Certifications and Approvals | ATEX / IECEx Approvals for Zone 0, 1 (details see page 17) North American Approvals Class I, Div. 1, 2, Gr. A,B,C,D, Zone 0, 1 American Bureau of Shipping (ABS) Product Type Approval for use on marine vessels |

Testing and Inspection | All sensors are hydro tested, calibrated and supplied with a traceable calibration certificate. Customized calibration and testing services are available |

Project Documentation and QA, Services | Rheonik offers a full set of services for large and complex engineering projects. •Certificates of origin and conformity, mill certificates •Data books including WPAR, WQS, NDT, test & quality plans, functional testing, calibration procedures, customized packing, factory acceptance etc. •Painting to project specification •Start up and commissioning services on/offshore |

Options | Enclosure heating for high temperature applications Cleaning for oxygen service , … For more consult factory |