Superior Omega technology

Rheonik was founded in 1986 with the sole purpose to develop the Rheonik Coriolis Mass Flowmeter range. After exhaustive testing of many different configurations, the unique design of the Omega tube meter with torsion rods and mass bars came into being and was granted a patent. E.g. unlike other Coriolis meters, the Omega tube design of Rheonik Coriolis meters has solutions for operation up to 1722 bar (24,969 psi) line pressure at a precision of 0,05 % and with renowned mechanical reliability.

The Omega product design

The Rheonik product range, due to the unique Omega loop, allows to serve extraordinary applications. It is the central element in and offers many advantages over traditional bending movements. Among other things, it allows the use of larger tube wall thicknesses, providing better resistance to abrasion and corrosion. Furthermore, the inner parts warrant a most stable design even using the thinnest tubes of sub 1 mm diameter for very low flow applications.

The design type is the key to Rheonik's wide and superior range of reliability and usability.

Heavy Wall

Thickness

Rheonik Omega design permits increased tube wall thickness for high pressure and higher temperature applications. The higher wall thickness also provides long-term stability and safety margin against potential abrasion and corrosion.

Stabilizing

Mass Bar

Our Mass bar works in conjunction with torsion rods to generate harmonic oscillation – tuning fork perpetual motion. That reduces susceptibility to external vibration and process borne dampening conditions.

Energizing

Torsion Rod

The energized Rheonik torsion oscillation produces, in concert with the mass bars, large oscillation amplitudes with extremely good signal to noise ratio for the best accuracies, even at low flow conditions. The stability of the oscillation is the key for highly reliable measurement in difficult conditions, i.e. bubbles in liquid or non-homogeneous fluids with different densities.

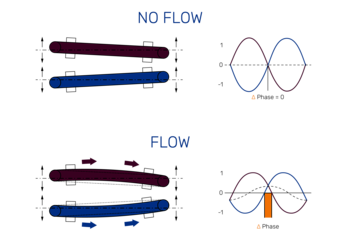

The Measurement Principle

Each mass flow meter has two measuring tubes. The oscillating system is driven by two controlled electromagnetic excitation coils. As liquids or gases flow through the oscillating omega tubes, the Coriolis force is created and causes a slight deflection of the two measuring tubes from their original shape. The opposing tubes are referenced to each other and the changes in deflection are proportional to the mass flow rate. In practice, the referencing is done by attaching small pickup coils that generate sinusoidal voltages. The degree of deviation of the phase shift is directly proportional to the mass flow.