RHE 49

TRANSMITTER

The RHE49 is an extremely compact Coriolis transmitter. The Rheonik AnyInterface Commitment provides a wide variety of communication options for seamless connection to control or SCADA systems. Options include Ethernet, Modbus, ProfiNet, EtherNet and others.

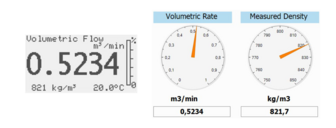

- Measures Mass Flow, Volumetric Flow, Density and Temperature

- Outputs: 1 x Analog, 2 x Frequency/Pulse/Status

- Inputs 1 x Digital

- PC USB / RHECom, RS 485 / Modbus RTU, Modbus TCP, Ethernet IP, Profinet, EtherNet, HART

- Optional Backlit Color LCD

- Installation in Hazardous Area

- Rheonik Assurance Factor®

Standard programming package

The Standard programming package provides the following measurement and function features:

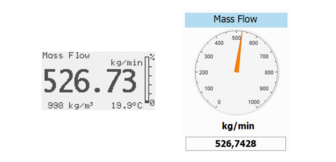

Direct Mass Flow Measurement

Mass flow is calculated using the Coriolis principle to provide a high accuracy Mass Flow measurement of the fluid or gas flowing through an Omega Tube Coriolis sensor.

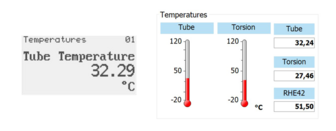

Temperature Measurement

Each Omega Tube Coriolis Sensor provides a temperature measurement from built in sensors.

Fixed and Calculated Density Function

The Fixed Density function allows to enter a fixed density value for volumetric flow calculations.

The Calculated Density function allows density to be generated based upon process temperature. A base/reference density at a known temperature is entered for the fluid being measured along with a coefficient describing the change in density per temperature unit. The firmware in the transmitter calculates flowing density based upon this information to use for volumetric flow calculations.

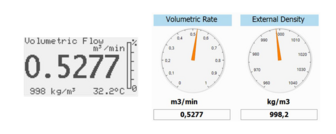

Calculated Actual Volume Measurement for Liquids and Gas

Volume measurement is calculated by dividing direct mass flow measurement by the Fixed Density.

Standardized/Normalized Volume Measurement for Gas

This function calculates the volume of gas passing through the meter at standard conditions. The density of the gas at standard conditions is entered into the transmitter and the volume is calculated using this in conjunction with the flowing mass.

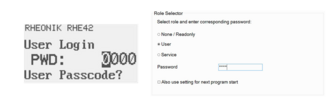

Password Protection

All setup and calibration parameters within the meter are protected with passwords to prevent unintentional or unauthorized change once installed.

Batch Controller

The transmitter is equipped with an onboard batch controller that, in conjunction with external pumps and/or valves allows the precise delivery of a preset mass or volume of process fluid on demand. Operated from the instrument front panel, remotely via operator switches or through digital communication from a connected supervisory control system, the controller is configured to utilize either a one stage or a two stage delivery strategy in ensuring the right amount of fluid is batched through the meter. The electronics self-learns, adjusting shut off times as more and more batches are delivered to further refine the amount of delivery, saving material costs and improving quality.

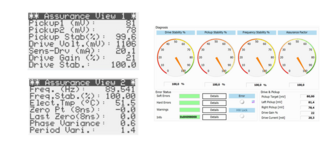

Assurance View® Diagnostics

Inbuilt self-monitoring functions are available that can be used to determine the reliability of the flow meter readings at all times. Diagnostics are quickly accessed through dedicated menu displays, RHECom software and the MODBUS interface.

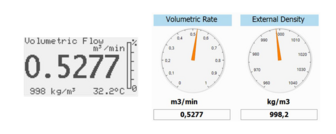

Density Operation Package

The Density Operation Package includes all features from the Standard Operation Package plus the following measurement and function features:

Direct Density and Volume Measurement

The flowing density of the fluid in an Omega Tube Coriolis Sensor is determined from the measured resonant frequency of the sensor and used to calculate instantaneous volumetric flowrate.

Brix/Baume Units

The unit can be configured to read out in °Brix or Baume. °Brix or Baume are used extensively in the sugar and beverage industries.

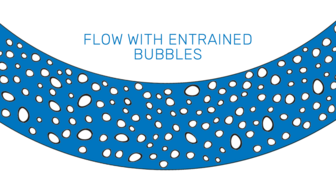

Partially Filled Pipe Management – Lite Version

Often referred to as multiphase flow, the flow regime in a partially filled pipe can cause large measurement errors and even create a measurement fault condition in a Coriolis Flow Meter. When PFPM is activated, density measurement is continuously compared to preset limits to determine if the sensor is seeing a liquid/gas mixture running through it. When multiphase flow is detected, it can be signaled, to alert users and allow action to be taken to minimize error. The full version of PFPM is available with the Assurance Diagnostics Package.

Assurance Factor Package

The Multifunction Package with Assurance Diagnostics Suite includes everything from the Multifunction package plus the following advanced diagnostic functions:

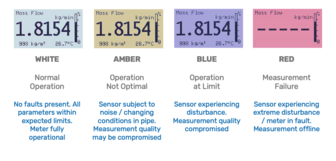

Assurance Factor®

Assurance Factor® is a numeric value generated by an internal algorithm that in indicates the overall health of the flow meter and measurement.

Assurance Factor® value can be used to trigger changes in screen color when the optional display is fitted to the RHE (White – Amber – Blue – Red), providing highly visible wide area condition indication.

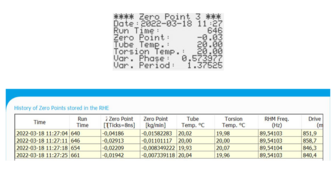

Zero Point Setting History/Statistics

The AF advanced diagnostics package log the last 10 zero points for inspection and troubleshooting. Zero point setting is very dependent upon installation conditions and is therefore specific to each sensor in the field. Comparing zero point history can help identify installation and operation issues that could effect accuracy and performance of the flow meter.

Partially Filled Pipe Management – Full Version (PFPM)

In this full version of the PFPM function, two different monitoring methods are used, either separately or in conjunction with each other, to detect when mixed phase fluid is flowing through the Coriolis flow sensor. When the PFPM function is in operation, density measurement and/or sensor pickup voltage levels are closely monitored to determine if the sensor is seeing a liquid/gas mixture running through it. Upon detection, actions can be taken to minimize measurement inaccuracy and process disruption. The program feature also allows “bridging” an interrupted measurement (e.g. heavy gas bubbles) for up to 60 s with the last valid measurement values.

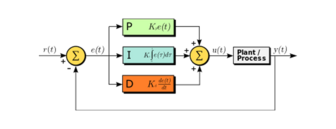

PID Controller

A PID controller is implemented in the transmitter to provide direct control to a valve or pump via a 4-20mA output for flow control purposes. The PID controller function features fully tunable PID parameters for either mass or volumetric flow rate. Set-point can be established via the front keypad/display or remotely via digital communication.

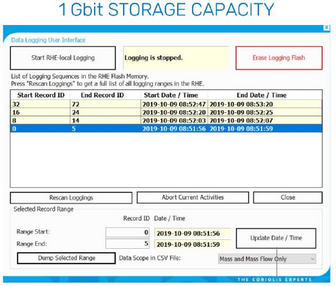

Data Recording

The fluid transfer package contains fully featured onboard data recording with a capacity to record over 500,000 time stamped records. Records include all measured variables and totalizers along with diagnostic data. Recording interval can be set from 1 to 600 seconds and recording started and stopped through the display user menu or via Modbus. Data is downloaded by request through Modbus. The RHECom software package provides a simple interface to configure the data recorder and download recorded data.

Custody Transfer Package

The Custody Transfer Package includes everything from the Oil and Gas Function Package plus the following features:

Precision Flow Analysis (PFA)

For fast fill applications down to 0.5 s duration measurements, transmitter update time can be increased to 4 ms. This allows a 250 Hz totalizer update rate (50 Hz is standard) to maintain very fast tracking of actual volume/mass delivered, and e.g. through the internal batch control function, results in a maximum signal delay of 10-20 ms to a connected control valve once the batch set-point is reached. Depending upon the speed of operation of the fill valve, repeatable accuracies of better 1 % are achievable for filling operations of 500 ms duration and less.

Hardware Lock Switch

For applications such as custody transfer where sealing is required. This switch, when engaged, prevents change of any setting within the transmitter through both the user panel interface and through a digital communications port. To accommodate some special customer needs the Lock Switch configured to leave a totalizer reset and/or a zero calibration possible.

Once the Lock Switch is set, a tamperproof seal can be applied to the transmitter case to indicate if the transmitter has not been opened since sealing.

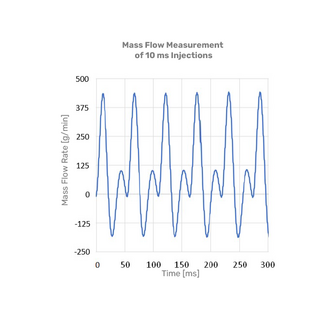

Fast Response Package

For applications requiring an extremely fast response to flow e.g. extremely fast filling applications of less than 500 ms, the transmitter offers a unique Fast Response Package.

Fast Response Package

For extremely fast fill applications down to 5 – 10 ms measurements, a patented fast response filter technology is employed within the transmitter to speed up measurement update time to better 1 ms. With an additional internal fast sampling mode this allows a 4 kHz measurement update rate to maintain very fast tracking of actual volume/mass delivered, and e.g. through the internal batch control function, results in a maximum signal delay of 1ms to a connected control valve once the batch set-point is reached. Depending upon the speed of operation of the fill valve, repeatable accuracies of 0.5 % are achievable for filling operations of 500 ms and less.

The fast fill function has a variety of tuning parameters and their setting will largely depend on the operating conditions (temperature, pressure, density, target delivery, etc.) of the filling system. For users of the Fast Response Package, Rheonik will provide assistance with initial configuration and tuning of the transmitter. The tuning parameters can be further optimized on site using the Precision Flow Analysis Tool.

The unique Precision Flow Analysis (PFA) tool allows data sampling of up to 4 kHz (requires a Modbus TCP/IPv4 connection) and subsequent analysis. By transferring the data into a calculation spread sheet the fluid dynamics can be graphically reviewed – a powerful help to optimize a sophisticated fluid handling system e.g. such as a satellite engine.

The Fast Response Package includes all functions and features of the Fluid Transfer Package.

Contact us for further specification

Our features and packages are extensive and cover most applications.

If you face a special challenge, we are happy to help you implement new solutions.