Custody Transfer & Allocation Metering

Rheonik – the partner for your oil & gas applications

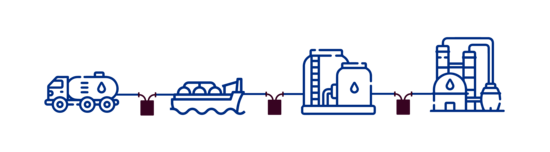

In the sale and purchase of liquid products, an ability to accurately measure the amount of material transferred is of great value to all parties involved in the transaction. The use of high accuracy flow meters in transfers such as raw or refined petroleum products between tanks, tankers, ships, pipelines, barges and trucks ensures the satisfaction of both buyer and seller.

Typical Applications include

- LACT metering

- Cargo offload and export metering

- Pipeline delivery systems

- Truck and railcar loading

- Internal Allocation metering

Highly accurate and

reliable measurements

The intrinsic accuracy of Rheonik Coriolis Mass Flow Meters makes them ideal for both custody transfer and allocation metering applications. Certifying bodies worldwide have already put their seal of approval on Rheonik meters, both large and small. Many users are benefiting from the high accuracy and stable, reliable performance that are trademarks of the unique omega tube design employed in all Rheonik flowmeters.

Rheonik meters are available in line sizes up to 12” and throughputs of up to 1500t/hr. They provide comparable performance to positive displacement and turbine meters without suffering the same high costs of installation and maintenance.

For custody transfer applications, meter accuracy can be periodically checked in line using a fixed or mobile prover in exactly the same way as existing meter technologies. Rheonik Coriolis Mass Flow Meters have multifunction capability with flow, density, and temperature outputs and feature built-in calculations to API standards for volume standardization.

All Rheonik meters can be field calibrated and operate in accordance with API MPMS Chapter 5.6 – the Use of Coriolis Meters for Custody Transfer. They are fitted with sealable hardware lock switches to prevent unauthorized change to setup and calibration parameters.

For applications requiring multiple meters, Rheonik meters can be manifold mounted in parallel and meter output summed in a local flow computer station. Meters installed in parallel can be factory tuned to different operating frequencies (in accordance with API MPMS Chapter 5, Section 6, 6.3.7) to prevent errors caused by frequency crosstalk. When installed in this way, a bank of Rheonik Coriolis Mass Meters has a significantly more compact footprint when compared to other technology meters.

Rheonik Coriolis Mass Flow Meters are available for all custody transfer applications, are sized for flow rates from 0.004 kg/min (0.009 lb/min) up to 30.000 kg/min (66.139 lb/min), have pressure ratings up to 20,000 psi, and function in temperatures from -196°C (-321°F) up to +210°C (410°F). Line sizes range from fractional tube up to 12”. Wetted materials are stainless steel as standard but can be supplied in Hastelloy/other nickel alloys for corrosive applications or Super Duplex for high pressure. All Rheonik meters are suitable for hazardous area installation.

What flow measurement challenge do you have that we can solve together?