Use of Rheonik products in

hydrogen and carbon processes

Investment in sustainable success and future-proof growth

Anthropogenic climate change is one of the greatest challenges of our time. To counteract the rise in greenhouse gases, measures to reduce CO2 emissions are essential. One way is to switch to renewable energy or to use energy-efficient, climate-neutral technologies and energy sources - such as hydrogen.

Hydrogen can help fight climate change and create a sustainable future in several ways. First, hydrogen can be used as a clean fuel in industry, especially in steel production. Here, hydrogen can be used as a reducing agent to separate the iron from the ore, acting as a reducing agent instead of carbon. Another important application of hydrogen is mobility. Hydrogen can be used as a fuel for vehicles that produce only water as an exhaust. Fuel cell vehicles are equipped with electric motors and can achieve a range and performance similar to conventional vehicles. Finally, hydrogen can be put into storage and used to buffer intermittent renewable energy supplies.

Another option is carbon capture and storage, in which carbon dioxide is captured from the exhaust of power plants and other industrial facilities and stored in geological formations.

Building the right infrastructure for the future early on not only helps protect the environment, it can redefine and future-proof entire business units.

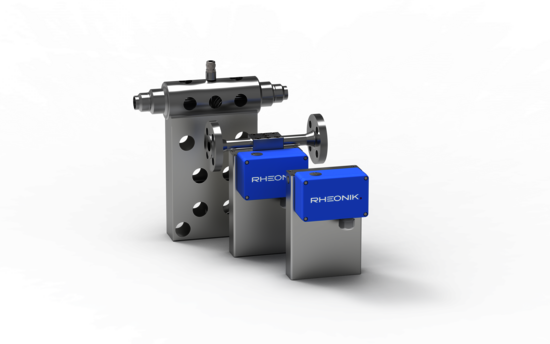

Why Rheonik Coriolis mass flow meters?

At a temperature of -56.6 °C (-68,88 °F), carbon dioxide gas changes to a liquid state. Hydrogen, on the other hand, changes at a temperature of -252.9 °C (-423,22 °F). Rheonik Coriolis mass flow meters can reliably and accurately measure both liquid and gas states, making them a valuable addition to H2 and CO2 processes.

Hydrogen & Renewable Energy

More and more of our energy comes from renewable clean energy sources like solar, hydro and geothermal. As technology to harness this energy has evolved, larger scale plants taking advantage of these natural resources have been created and with them, the need for performance and efficiency measurements. Rheonik Coriolis mass flow meters play a major role in ensuring energy from renewable energy sources remains part of our day to day energy makeup.

Applications

- SAE J2601 Hydrogen dispensing

- Solar panel oil circulation

- Turbine lubricant monitoring

Advantages

- Extremely high pressure ratings

- Industry standard high ressure connections

- Specialist materials of construction to combat embrittlement

- High temperature ratings

- Custody transfer accuracy

- Certified according MID MI-002, OIML R 137-1&2:2012

- Certified according CS OIML R139

- Compact pipe footprint

- Liquid and gas measurement

- Maintenance free

- Intrinsically safe sensor suitable for zone 0

- Resilient to external vibration

- No moving parts

- Rheonik Assurance Factor© feature, comprising meter self diagnostics online at any time

Leading in H2 mass flow measurement – since 1999

Hydrogen fueled vehicles have become a common sight in areas where investment has been made in the “hydrogen highway” to establish filling stations and fuel supply to support such vehicles on the road. America, Canada, Japan, China and many European countries have already invested large sums of money to establish a basic network of hydrogen stations supporting fuel cell cars. With many fuel cell vehicles from several manufacturers already on the road and with many more to come, the hydrogen highway will continue to be expanded to provide the capacity needed to keep them running.

Rheonik is a pioneer in the hydrogen fuel cell revolution. From the very outset, Rheonik has worked with all of the major hydrogen suppliers to produce flow meters that are both accurate and can handle the extremely high pressures associated with hydrogen distribution and dispensing.

The implementation of clean fuel technologies such as that found in hydrogen fuel cell vehicles is an increasing priority for many countries as concerns about global warming and its effect on the planet continue. Rheonik are proud of their contribution to the industry and will continue a program of improvement to provide even better solutions and performance to support these important global warming reduction initiatives.

Hydrogen is transferred to storage and into fuel cell vehicles at very high pressures, high velocities and at varying temperatures. The provision of a flow meter to measure under these conditions is not trivial as it must be both accurate, reliable and usable for end user point-of-sale billing. Rheonik Coriolis mass flow meters have proven to be, and continue to be, the most reliable meters for H2 measurement available.

Filling Stations

Hydrogen fuel dispensers are becoming a familiar sight alongside gasoline and diesel dispensers in many filling stations around the world. Fuel cell vehicles are able to pull up, connect a hose and fill up their tanks just like vehicles using traditional petroleum based fuels. The heart of a hydrogen dispenser is the point of sale flow meter. Meters must be Weights and Measures approved, tested and sealed to ensure end customers receive the amount of hydrogen they are paying for. Sold in mass (kg), Coriolis meters are ideal for the service as they read primarily in mass and have a large measurement turndown capability that can handle the flow regime of high flow at the fill start to low flow at the end. Methods have been developed to qualify Coriolis meters for H2 service using certified weigh scales and like their petroleum counterparts, hydrogen dispensers can be certified and sealed by local Weights and Measures officials, a protection for consumers.

The vast majority of hydrogen dispensers around the world are fitted with Rheonik Coriolis mass flow meters. Dispenser manufacturers everywhere are confident that when a Rheonik meter is installed, it will provide the performance and reliability that they, their customers and the hydrogen buying public require and demand.

H2 Distribution

While a few filling stations have a pipeline supplying them with Hydrogen 24/7, most do not and it falls to trucks equipped with high pressure tube trailers to deliver Hydrogen to local storage at filling stations from the point of generation. The same applies for the delivery of Hydrogen to industrial customers. In order to control and account for the amount of gas being delivered, each truck is equipped with a flow meter that totalizes the amount of each gas transfer.

Rheonik Coriolis mass flow meters are fitted to tube trailers to provide records of all gas either loaded to or unloaded from the trailer. Rheonik meters are rugged and can stand up to the rigors of road transport and their compact size makes them the very best option when installing in side enclosures and housings, a real challenge for other meters that are bulky and large. Transmitters are operated directly from the truck 12Vdc battery supply, removing the need for additional power supply converters or external sources. Transmitters can also be tamperproof, sealed against unauthorized change of configuration and settings to protect the integrity of the measurement at all times.

Technology Testing

As development in the hydrogen fuel cell industry continues, the need for proof of concept and performance testing increases. Rheonik have partnerships with major testing and standards labs around the world where Rheonik Coriolis mass flow meters are used as primary measurement devices in test equipment used for evaluation of new and better technologies.

Our partners trust Rheonik meters to give them the very best information for flowing Hydrogen streams as they investigate new components and systems from industry and regularly consult with our sensor team to ensure their measurement systems are constructed to give the very best results.

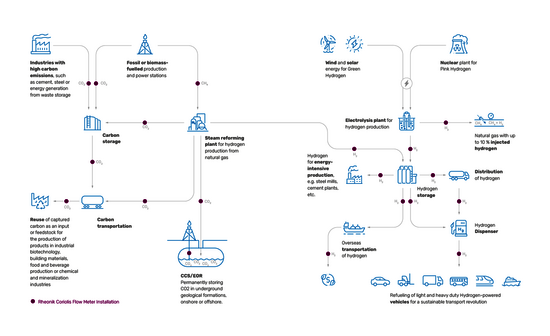

From oil & gas expert to carbon expert - with the same products

CCUS is an acronym for Carbon Capture, Utilization and Storage. This CO2 reduction technology is used to prevent the release of CO2 into the atmosphere from the combustion of fossil fuels such as coal, oil and gas.

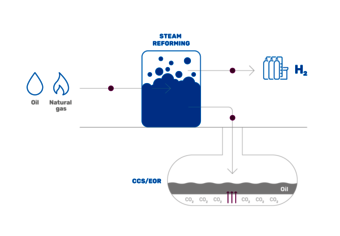

The production of hydrogen from natural gas (CH4) produces CO2 as a waste product. Natural gas contains many hydrogen atoms that can be released through steam reforming. For every ton of hydrogen produced, ten tons of CO2 are created, which must be stored to prevent it from escaping into the atmosphere.

Permanent underground storage of CO2 in structures such as salt domes and in nearly depleted oil and gas fields helps reduce CO2 emissions. Captured dense phase CO2 is transported through pipelines to wellheads, where it is injected underground. In nearly depleted oil fields, injection of CO2 maintains reservoir pressure and allows continued recovery of oil – a process called Enhanced Oil Recovery (EOR).